PSL012-302 | PSL012-304 | PSL012-303 | PSL012-301 Bearing | Radial Cross Sectional Split Ball Bearing

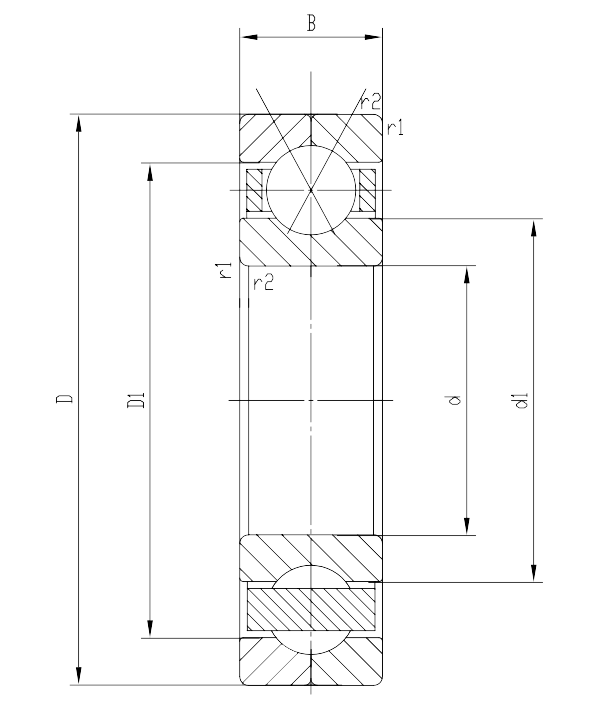

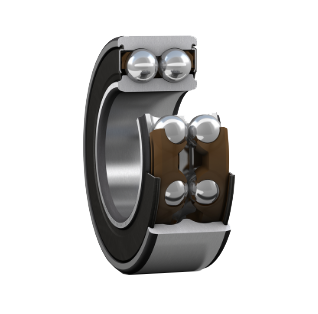

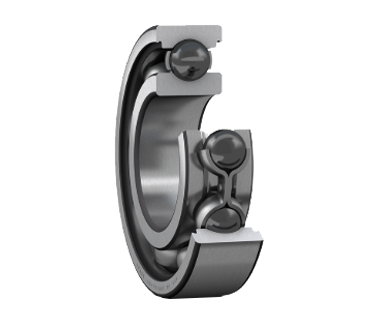

Luoyang HUANA Precision Bearing Technology Co., Ltd Produced PSLseries bearing PSL012-302、PSL012-304、PSL012-303、PSL012-301、PSL012-312、PSL012-305、PSL012-300 Radial cross-section precision thin-walled ball bearing with split outer ring structure. The product has the characteristics of short production cycle, high product accuracy, etc., which have been solved one by one by our technical personnel. Received multiple positive reviews from European customers and received consecutive returns.The four point contact outer ring two hemisphere bearing is a specially designed bearing that combines multi-point contact and split outer ring structure, suitable for complex loads and high-performance requirements. Here is a detailed analysis of it:1、 Definition of Split BearingSplit bearing is a special type of bearing, also known as an "open bearing" due to its unique structure. The structure of a split bearing is to separate the outer diameter and inner diameter of a ball or roller, making it easy to install, disassemble, and maintain the bearing. Therefore, split bearings have the advantages of simple structure, easy maintenance, and light weight, and are widely used in mechanical equipment2、 Structure of segmented bearingsSplit bearings are usually composed of two rings with the same cross-section inside and outside. The number of point divisions on the ring can be flexibly set as needed. When the bearing is under load, friction is generated due to the movement of the ball or roller in the ring, supporting the movement of the shaft and other rotating mechanisms.3、 Classification of segmented bearingsAccording to their different shapes and structures, split bearings can be divided into various types, including single row spherical split bearings, double row spherical split bearings, tapered roller split bearings, etc. Different types of split bearings are suitable for different mechanical equipment and working environments.4、 The application of split bearings in the mechanical industrySplit bearings are an important component of the mechanical industry and are widely used in industrial production processes. For example, in fields such as steel, heavy industry, automobile manufacturing, shipbuilding, and aerospace, different types of split bearings are required. The application of split bearings can not only improve the service life of mechanical equipment, reduce energy consumption, and improve efficiency, but also reduce maintenance costs, improve production efficiency, and play an important role in promoting the development of the mechanical industry.By introducing the definition, structure, classification, and application of split bearings in the mechanical industry in this article, we can understand the importance of split bearings in the mechanical industry. The application of split bearings can not only improve the working efficiency and service life of mechanical equipment, but also greatly reduce maintenance costs and improve production efficiency. Therefore, split bearings are an indispensable and important component in the mechanical industry.

Tel

Tel WeChat

WeChat

Msg

Msg TOP

TOP